Please wait, loading...

Please wait, loading...

![]()

Rebar anchoring is a modern and effective method used for the rehabilitation and strengthening of concrete structures. This method is employed to connect new structural elements to existing ones and to bear various loads. The ACI 355.4-11 standard provides comprehensive guidelines for evaluating the performance of rebar anchoring systems. This article reviews the operational tests involved in assessing post-installed rebars and explains how each test contributes to the safety and durability of the structure.

Over time, the need for retrofitting and rehabilitating concrete structures has increased due to factors such as degradation, load changes, or structural expansion. Among the key techniques for this purpose is the use of post-installed rebars. Anchoring has become a specialized method in civil engineering, appreciated for its numerous benefits, such as the ability to reinforce without extensive demolition. It is widely used to join new structural components to existing ones, sustain heavy loads, and enhance the overall stability of structures.

Adhesive Rebar Systems – ABABOND by Abadgaran

The ACI 355.4-11 standard establishes a framework for qualifying and approving rebar anchoring systems. It includes a series of tests to evaluate the behavior of post-installed rebars under various operational conditions.

ACI 355.4-11 covers:

According to ACI 355.4-11, all tests must simulate actual loading and environmental conditions to ensure long-term system performance.

Key Operational Tests in ACI 355.4-11

1. Tension Test

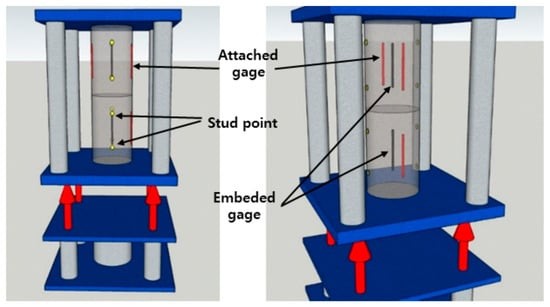

This is one of the most crucial tests to evaluate the tensile capacity and bond strength between the rebar and the concrete:

Purpose:

2. Creep Test (Under Sustained Load)

Creep is one of the key factors in long-term service performance. This test is conducted to evaluate the deformation of post-installed rebars over time under sustained load.

In this test:

Creep can lead to a gradual decrease in the load-bearing capacity of the system, making it essential to assess system behavior under long-term loading.

Environmental Conditions:

This test is performed at various temperatures and humidity levels to replicate real-world service environments.

3. Cyclic Load Test

This test is designed to simulate real-world conditions of cyclic or dynamic loading, including seismic events.

4. Elevated and Low Temperature Test

Temperature has a significant effect on adhesive performance:

Purpose:

5. Chemical Resistance Test

Used in chemically aggressive environments (acidic or alkaline):

Purpose:

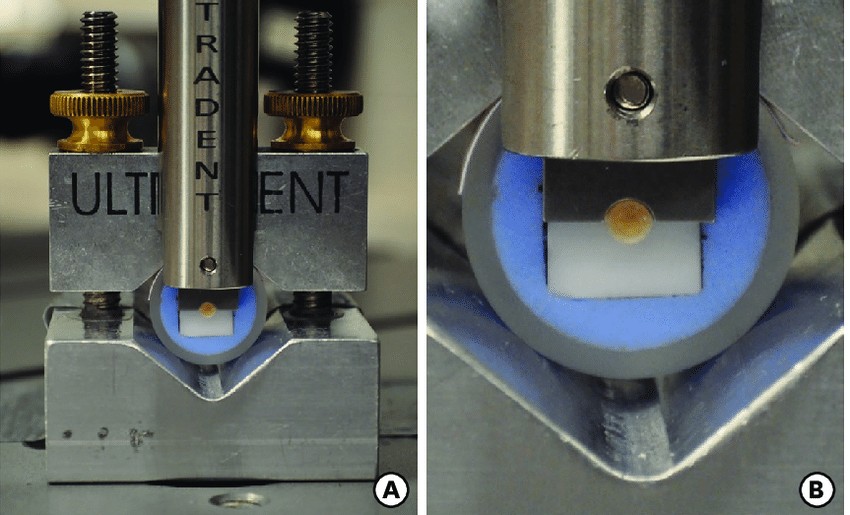

6. Pull-Out Test

This test measures the direct bond strength:

Purpose:

Adhesive Materials for Anchoring Systems

Adhesives like epoxy, polyester, and vinyl ester play a crucial role in rebar anchoring performance. Key properties include:

Operational test results provide vital information on system behavior, helping engineers to:

These tests are critical for the safety and service life of concrete structures. Incorporating them into construction projects enables better decision-making in both design and execution.

Recommended Product: ABABOND RA500 & RA600

For professional and reliable anchoring, Abadgaran recommends ABABOND RA500 and WA600. These adhesives offer high bond strength, excellent chemical and mechanical resistance, and easy application—ideal for anchoring rebars and bolts into concrete. Developed using advanced technology and in compliance with international standards, these products meet the rigorous demands of civil and industrial construction projects.

References: